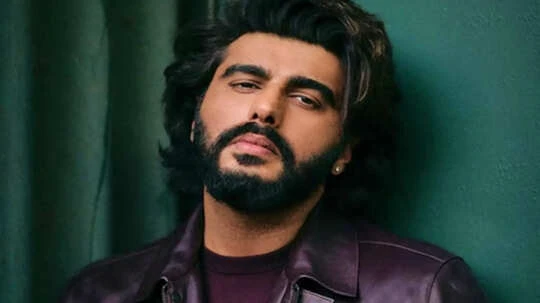

Arjun Kapoor has been working in the industry for more than 13 years. He made his acting debut with the film Ishaqzaade. Ever since he made his grand Bollywood debut, Arjun Kapoor has always been a hot topic of trolls for the netizens due to his filmy background.

In fact, he was highly criticised for his appearance in the AIB Roast show with Ranveer Singh. Amidst all, an airline staff recently penned a sweet letter to Arjun Kapoor, in which she mentioned, ‘I loved AIB roast’.

Airline staff sends letter to Arjun Kapoor

Arjun Kapoor happened to travel on an IndiGo flight where a staff member got smitten by his charming look. She penned a sweet letter to the Gunday actor. The letter reads, “Dear Arjun, It was a pleasure having you on board today! We love watching you on the screen. You have been amazing so far, and we wish you all the very best for your future projects as well. PS. I loved AIB Roast! Warm Regards, 6E 2775.”

Reacting to the sweet gesture, Arjun Kapoor shared a picture of the note on his Instagram story and wrote, “IndiGo your crew as always is very kind.”

For the unversed, the AIB Roast show was a diss show, which was heavily criticised for its abusive language and controversial slurs on several renowned people in India. Karan Johar was also a part of it.

Coming back to Arjun Kapoor, the actor was last seen in Mere Husband Ki Biwi alongside Rakul Preet Singh and Bhumi Pednekar. Arjun’s performance in Singham Again was loved by many people. The film was a moderate success at the box office. !