New Delhi: Researchers from the International Institute of Information Technology, Hyderabad (IIITH) and King Abdullah University of Science and Technology (KAUST) have developed a low-cost, flexible, pressure-sensitive material for use in healthcare, robotics and wearable devices. The team has demonstrated two real-world applications, a smart computer interface where the sensor reliably detected single and double mouse clicks, as well as a wearable glove. In the latter application, the sensor could determine the weights of the objects being grasped, which has potential applications in robotic grip control and biomedical feedback systems.

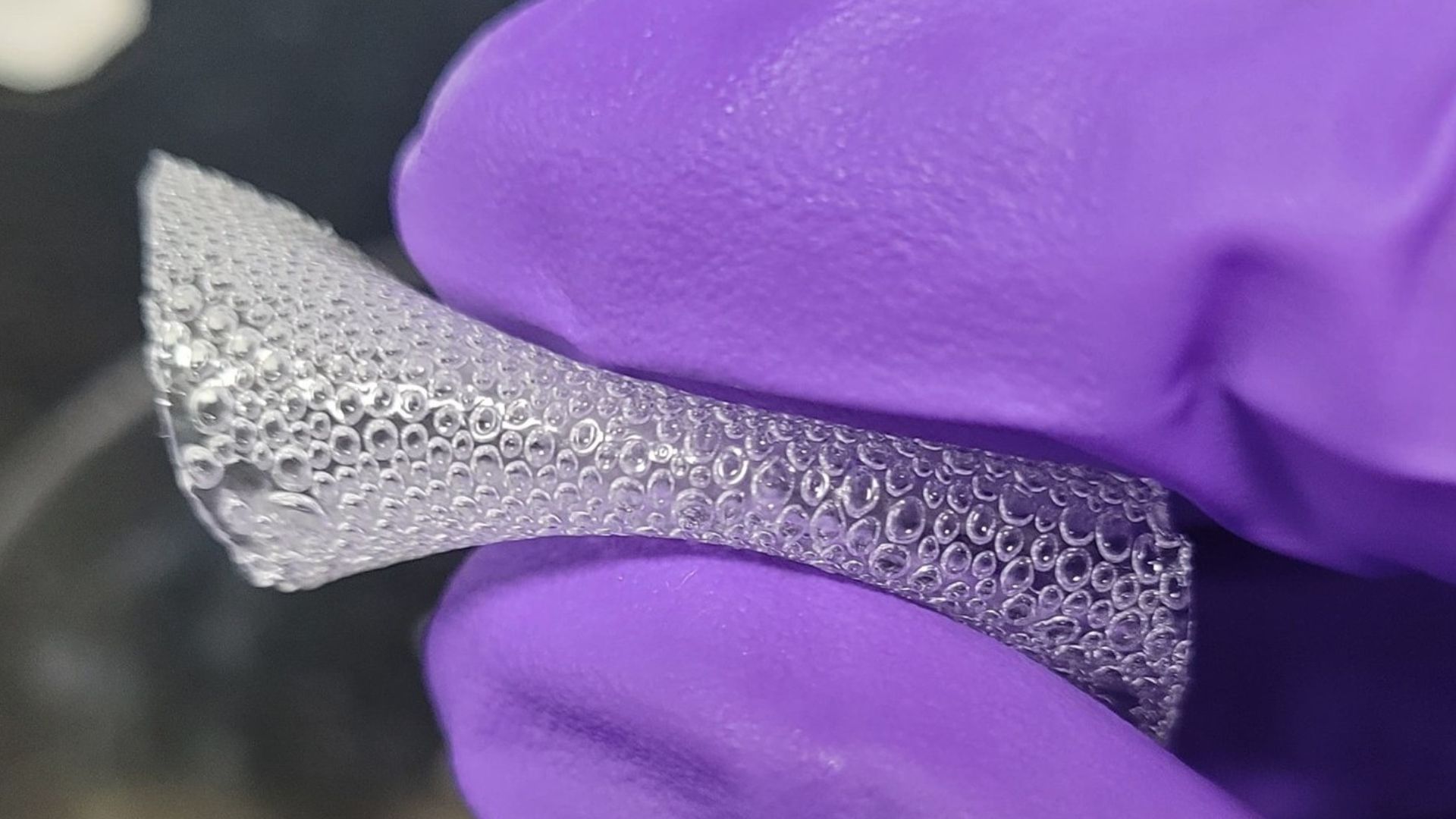

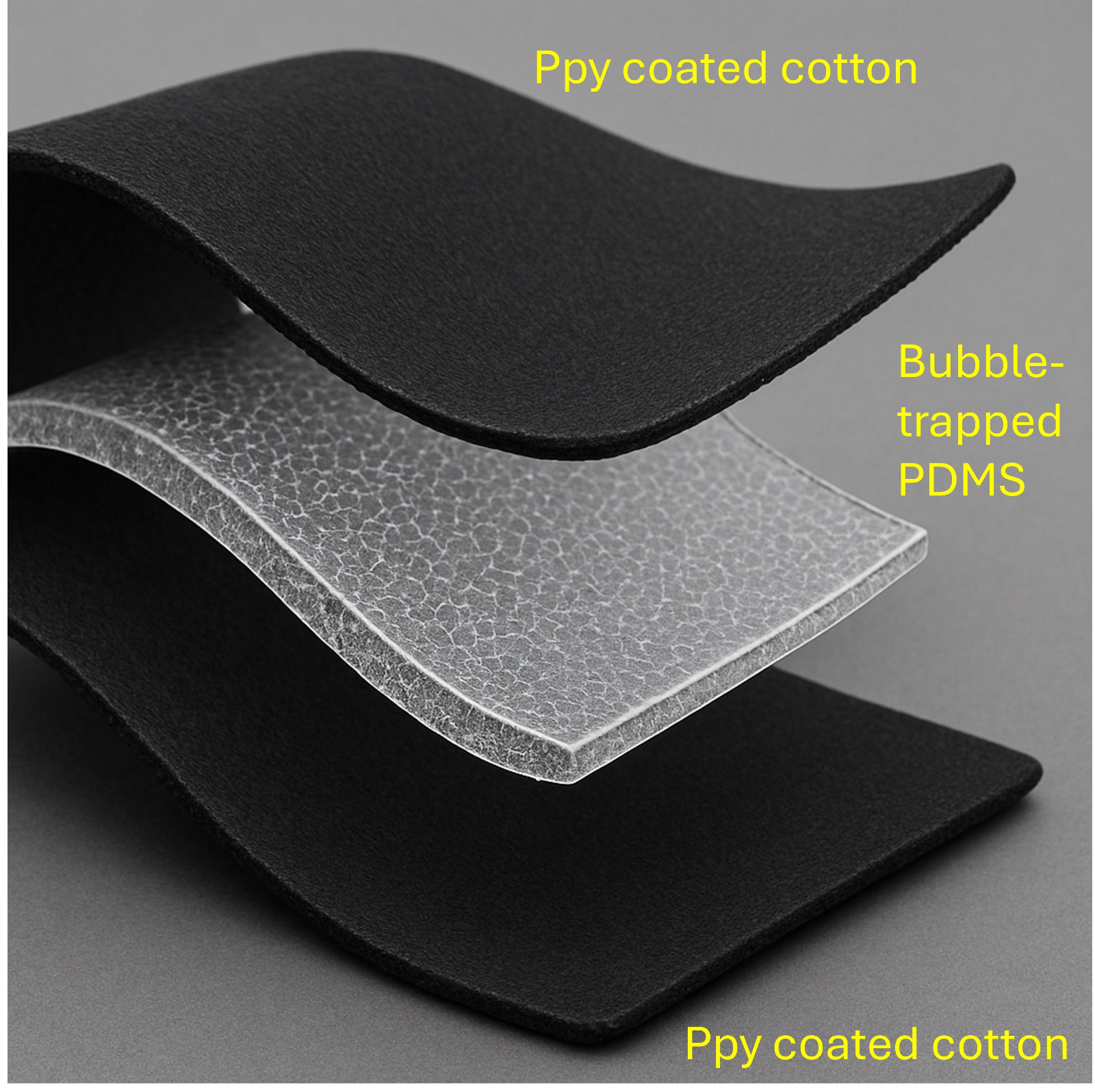

The flexible, stretchy foam is sandwiched between layers of conductive cotton. (Image Credit: IIITH/KAUST).

A paper describing the research has been published in the IEEE Journal on Flexible Electronics. One of the study authors, Aftab Hussain, the Associate Professor at IIIT Hyderabad said, “Our fabrication approach uses everyday materials like cotton textiles and polymer foam, still delivers performance comparable to state-of-the-art flexible sensors. The PDMS foam created in this study has far reaching applications beyond sensors, because it is an emerging class of materials that provides more stretchability and flexibility than the base polymer. This opens up opportunities for affordable and customizable materials for healthcare and assistive technologies.”

A wide variety of potential applications

The material is sensitive to pressure, and is made up of layers. The bubble-filled polydimethylsiloxane (PDMS) foam returns to its original shape after the pressure is applied. The cotton fabric is coated with a conductive material called polypyrrole. When pressed, the foam squishes, changing the electric signals between fabric layers, informing a computer on how much pressure is applied. It is reliable, fast and does not wear out, making it suitable for use in smart gloves, surgical robots or futuristic wearables. This material is easy to produce at scale. The material can provide machines with a sense of touch, knowing how much pressure to apply when holding an apple or a lightbulb.