Only Elon Musk could have done it.

Which is to bet on a novel technology, select a counterintuitive site for the refinery, reimagine conventional engineering norms, and yet build it faster and cheaper than anyone else in the world.

I am not entirely sure Musk is human.

So, about 7 hours ago (as this column is being written) when Elon Musk announced on X as a matter of fact that “the largest Lithium refinery in America is now operational”, it must be with some pride.

Just look at what the man has achieved: a) he has built America’s first lithium refinery, b) employed a novel refining technology whose only byproduct is a powdery sand that can used in making concrete, c) got the refinery up and running fully in less about 30 months (from groundbreaking in May 2023 to full production end of 2025), d) spent less than a billion US dollars on it; while that’s almost 3x of Tesla’s initial estimate, it’s less than half of what conventional lithium refineries cost.

How did Musk Do It?

The short answer: just like he does everything else—by employing a first principles approach and rejecting the conventional, “this is how it’s done” mindset.

Traditional lithium refining relies on sulfuric acid and sodium hydroxide, and produces hazardous waste that requires careful and costly disposal. If a refiner cuts corner, then it’s the local environment that pays the price.

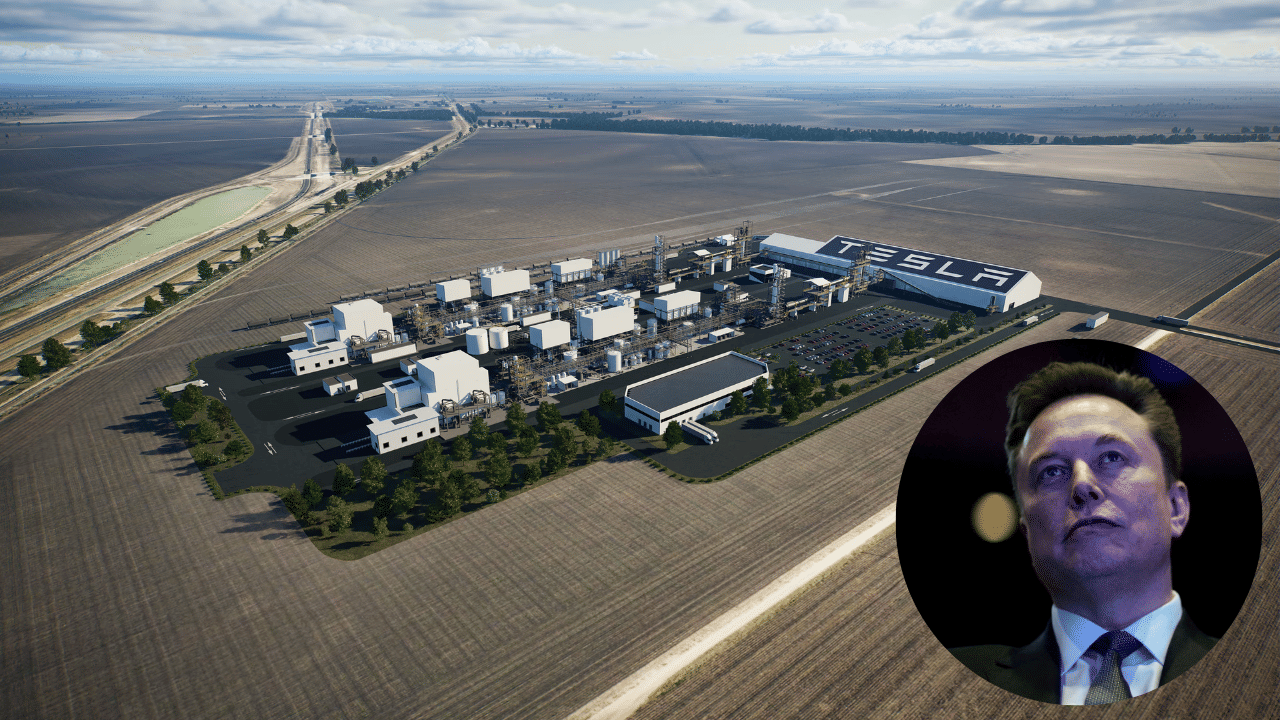

For the 1,200-acre Corpus Christi refinery, Tesla reengineered the process using low-toxicity industrial reagents and an alkaline leach method that allows it to convert spodumene (a hard-rock lithium ore that the US has plenty of) directly into battery-grade lithium hydroxide.

Instead of producing any hazardous byproduct, this refining method produces a useful co-product called analcime, which can be used in construction materials and concrete. Apparently, this process is also more energy efficient, consuming 35% less natural gas than conventional refining.

Then, Musk also threw in his classic chutzpah into the project. As per reports, construction began even before proper approvals were received from authorities; different phases of the project were executed not sequentially, but concurrently! For instance, Tesla’s project team ran feasibility studies, engineering design, permitting, procurement, and construction concurrently. This is a technique previously used by Tesla for its Gigafactory in China, which went from groundbreaking to production in a record 12 months.

A Leg-up for America

Tesla’s lithium refinery can support 50 GWh of battery production, which is enough to power 1 million EVs. So far, the US has relied on China for its battery-grade lithium, getting almost 75% of its requirement from Chinese suppliers. In 2026, the US demand for battery-grade lithium is projected upwards of 200 GWh, including 2 million EVs and other (consumer and industrial) energy storage systems and devices.

That means the Tesla refinery will take care of a quarter of that demand. It’s a big number and something that insulates Tesla cars from the vagaries of battery-grade lithium prices. For instance, in January this year its prices surged by 65% over December 2025, and a steep 105% year-over-year. For the larger global market, though, Tesla’s new capacity will have limited impact.

Just the same, the Tesla refinery marks an important step in America’s self-reliance in lithium refining, especially one that is environmentally friendly too. It makes America less vulnerable to weaponization by China of raw materials by enabling local production and sourcing. More broadly, it once again proves the power of American innovation and what entrepreneurs like Musk can achieve—while reminding America why it needs extraordinary immigrants like Musk.