By Ruchika Gupta – From the phone in your hand to the fan that cools your room, from metro trains to fighter jets ..rare earth magnets power everyday life in India. Yet, nearly 80 per cent of them still come from one country: China. With a Rs 5,000 crore government push and new recycling innovations, India is now racing to flip this dependence and build its own secure supply chain.

China dominates the rare earth ecosystem, accounting for nearly 69 per cent of global production and over 90 per cent of processing. In FY 2024-25, India imported about 57,000 tonnes of permanent magnets, with 93 per cent coming from China. Over the past decade, this dependence has only deepened – rising from 78 per cent in 2012 to almost 97 per cent in 2023.

This concentration gives Beijing enormous leverage over India’s future industries, from electric vehicles to defence and clean energy. Export restrictions on key elements like neodymium and samarium in 2024 briefly shook global supply chains, exposing India’s vulnerability. Although curbs were later lifted, the threat remains.

Attero’s Bet on Recycling

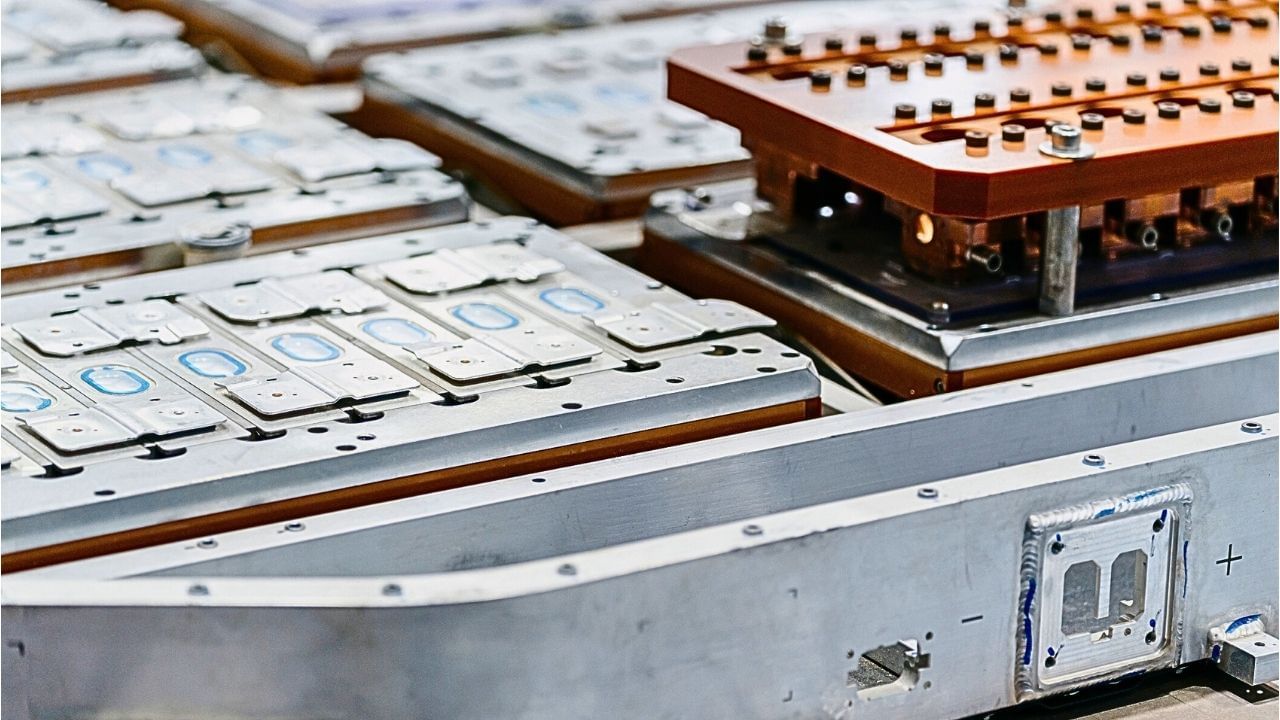

In conversation with Attero CEO Nitin Gupta, the company’s mission is clear – to help India build an independent and sustainable magnet supply chain. “We are already producing 1 tonne of rare earth oxides per day through recycling magnets,” Gupta explains. “With an investment of Rs 100 crore, we are scaling this up to 100 tonnes per day and setting up a state-of-the-art rare earth magnet manufacturing facility.”

This approach doesn’t just cut imports; it ensures supply security for sectors where delays can cost lives – defence systems, renewable energy, and electric mobility.

Hidden Minerals in Your Pocket

Most citizens may not realize it, but their smartphones contain nearly one-third of the periodic table, including 15 critical minerals and 9 rare earth elements. Even BLDC ceiling fans, sold as energy-efficient appliances, rely on rare earth magnets. Attero’s recycling technology recovers 22+ metals, including neodymium, praseodymium, cobalt, and lithium, at >98 per cent recovery rates and up to 99.98 per cent purity.

“With over 46 global patents, our work enables a circular economy that lowers costs and makes advanced technologies more accessible for everyday Indians,” Gupta says.

From Seelampur to the Supply Chain

India generates 3.8 million tonnes of e-waste annually, much of it processed in informal hubs like Seelampur and Moradabad, where workers risk their lives in crude recycling practices. Attero says it is working to change this. Initiatives like Selsmart (D2C take-back with rewards) and Metal Mandi (linking informal traders to the formal economy) aim to create safer jobs and dignified work.

“Waste pickers must be recognized as essential contributors to the circular economy,” Gupta argues. “With training, protective gear, and formal integration, we can save lives, recover more metals, and reduce our import bill.”

Strategic Sectors: Defence and Green Energy

Magnets are critical for missile guidance systems, drones, radars, EV drivetrains, and wind turbines. Any disruption in supply poses a national security risk. Attero is investing in R&D to develop high-spec neodymium and samarium cobalt magnets tailored for defence and renewable energy.

“The focus is on quality, indigenisation, and resilience so that India is not just self-reliant but globally competitive,” Gupta says.

Policy and People Power

The government’s proposed Rs 5,000 crore magnet scheme and the Critical Minerals Bill with a Rs 32,000 crore allocation for exploration underline India’s intent. But Gupta believes success depends on targeted policies: PLI support for domestic magnet processing, subsidies for recycling infrastructure, skill development, and strict enforcement of e-waste collection.

Public awareness is also crucial. “People need to see waste not as garbage but as India’s future resource base,” he stresses.

Turning waste into wealth

Looking ahead, experts argue India can become a global recycling hub by building world-class e-waste and battery recycling plants in special economic zones, while leveraging trade agreements to import waste for processing. This could create thousands of green jobs and give India a new identity, not just a consumer of global supply chains but a leader in closing the loop.

For ordinary citizens, this shift will mean cheaper technology, cleaner air, new job opportunities, and a sense of national pride. “Sustainability and self-reliance can go hand in hand,” says Gupta. “India has the chance to show the world how waste can fuel resilience, growth, and security.”