Ball Pen Refill Making Business: Ball pen refill manufacturing is an opportunity with high demand and low cost. Machine setups, ink filling, nozzle fixing can earn millions from simple processes. Government schemes like MSME and KVIC can also get help.

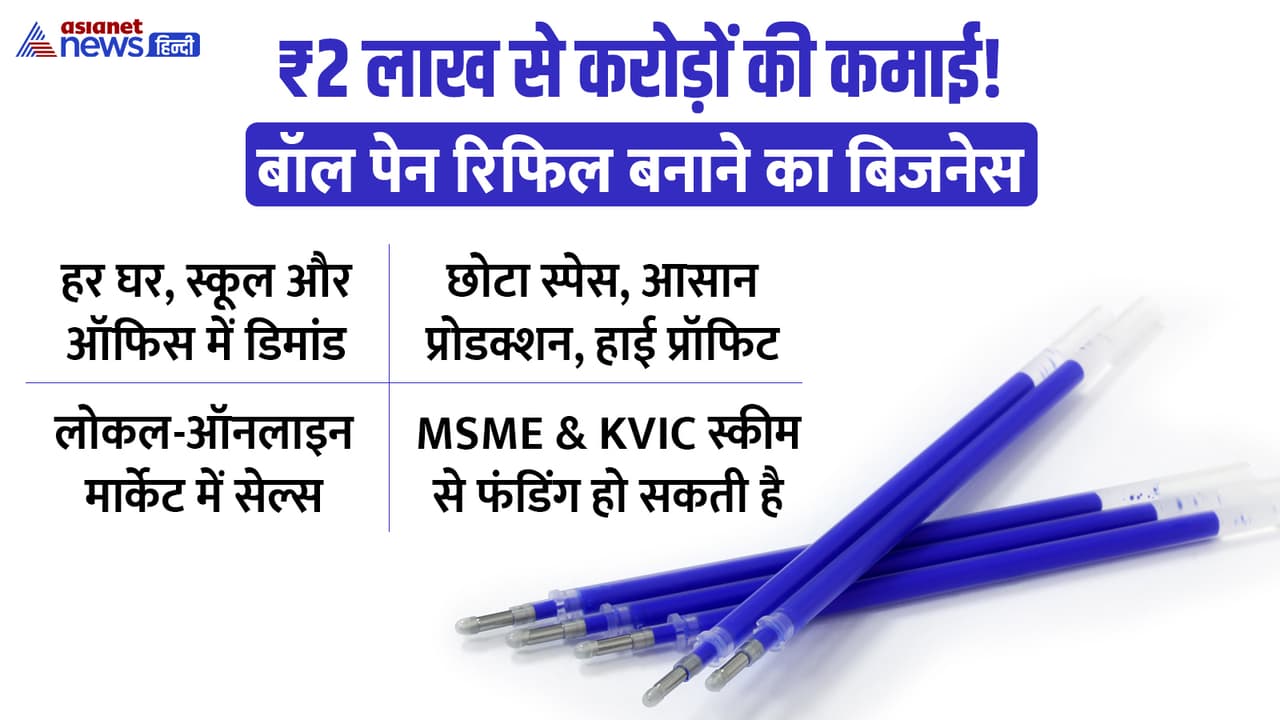

Business ideas: The demand for stationery products never decreases. Whether it is school, college, office or home, ball pen is used everywhere. This is the reason that ball pen refill manufacturing business can also become a profitable business on small levels. The special thing is that in this business, low cost, easy production process and constantly increasing demand can make you profit of millions every year. Let’s know how to start this business and how much can be earned in it…

Why do a ball pen refill business?

- Penn is a product that everyone uses, so its demand never stops.

- This is a low cost, high profit business. With an investment of about 2 lakh rupees, you can earn millions annually.

- The simple manufacturing process makes it special. Just ink is to be filled, nozzle and packing.

- There is good demand in the local and national markets. From small shopkeepers to large stationery companies, your market can be made.

How does a ball pen refill become?

- Ink filling is filled in the tube.

- Refugging from the refills to remove the ink smooth.

- Nozzle is placed in the tube.

- Refill is packed after hot stamping, packing and branding.

How much will be spent in ball pen refill business?

Raw Material: 1 lakh rupees

Equipment (punching machine, ink filling machine, centrifugging machine, hot stamping machine): 50,000 rupees

Working Capital: About 1.5 lakh rupees

Total project expenses: According to the Project Profile of Khadi and Village Industries Commission (KVIC), the total cost to start a ball pen refill unit comes ₹ 2,24,071.

Production and profit of ball pen refill manufacturing unit

Estimated annual production capacity: About 2.5 million refills

Projected Sales: 4.3 Lakh (Per Cycle)

Cost of Production: About 3.2 lakh rupees

Net Profit: 26,000 to Rs 36,000 per bicycle (dependent on capacity and sales)

Annual Net Profit: 2.5-3.0 lakh rupees (Production increases, earning can increase even more, sometimes it can reach crores.)

Details of expenses in ball pen refill manufacturing unit

Skilled & Unskilled: 6,000 rupees

Admin expenditure: 7,000 rupees

Overhead: 15,000 rupees

Insurance: 1,500 rupees

Depressation: 5,000 rupees

Interest (on loan): 29,129 rupees

Where is the demand for ball pen refill?

- Heavy demand in education sector ie schools and colleges.

- In the daily use of corporate sectors such as offices and professionals.

- Demand for small shopkeepers and stationery shops.

- Supplies on online platforms such as Amazon, Flipkart and other e-commerce sites.

What to do before starting the business of ball pen refill?

- MSME will take registration, GST and trade license.

- The machine has to be setup. Install ink filling, punching, nozzle fixing and centrifugging machine.

- Buy raw materials such as tubes, ink, nozzle and packing materials.

- Train skilled, ugly laborers.

- Cell on local shops, wholesalers and online platforms for marketing and distribution.

Benefits of ball pen refill business

- Always high demand product.

- Low space and low investment can begin.

- Women and rural youth can also run easily.

- Government schemes (KVIC and MSME Schemes) can provide financial assistance.

Disclaimer: This article is only for information. The financial and business information given in it is derived from kviconline.gov.in. Possible profits and risk in this business depends on different markets, locations, scale and product quality. Before investing, consult your financial advisor or business consultant.

Also read- Laundry Soap: Demand in every house, earning millions every year, learn how to start laundry soap business

Also read- Save electricity, earn money! Make strong profits from LED bulb, demand will never end